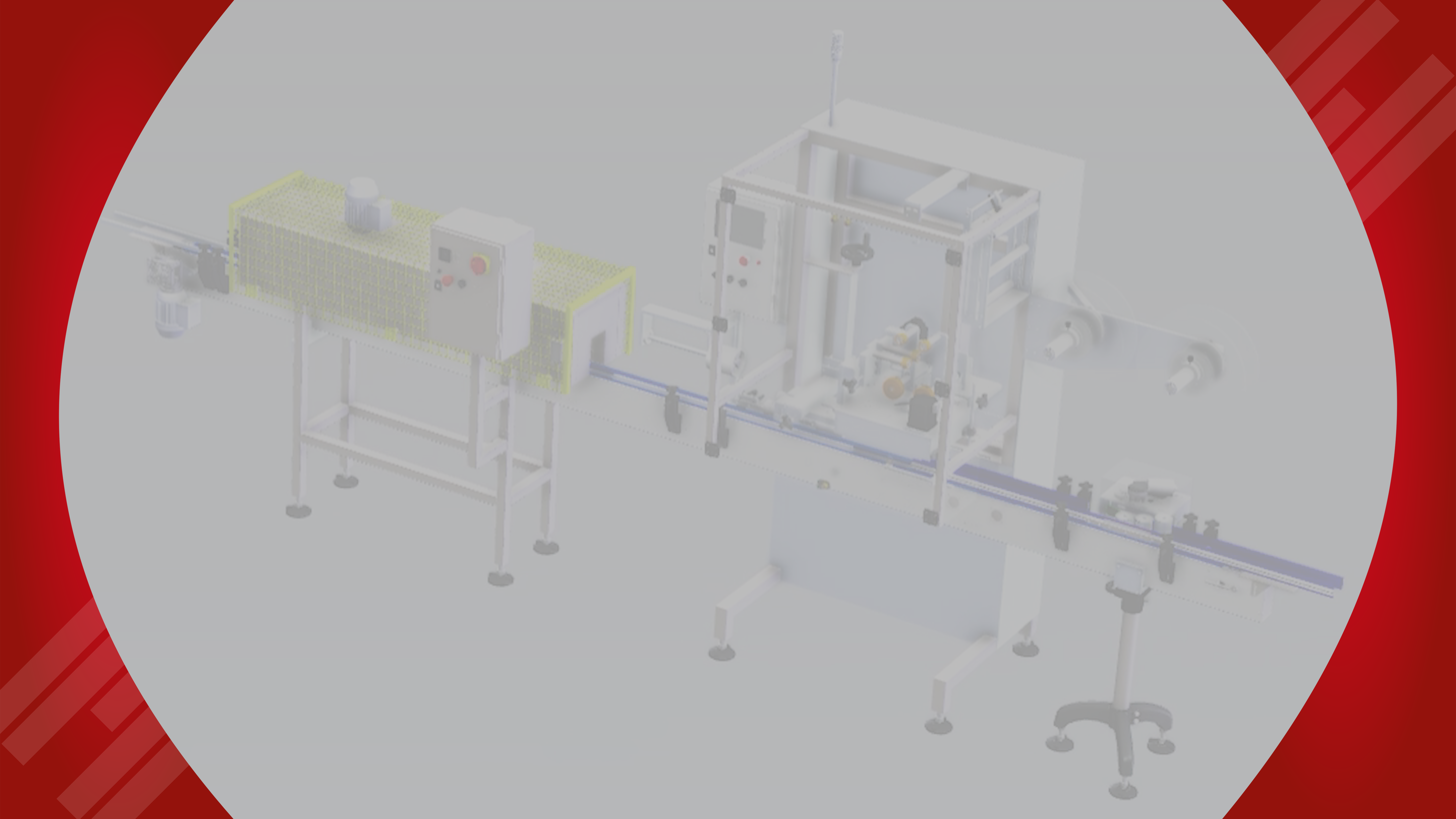

Maqmundi, with a long history in the development of labellers for the self-adhesive system, officially launches its labeller for shrink-wrapped bottles and labels, the equipment, called MAQ-SLEEVE, is available in two models: ONE and PLUS.

Maqmundi Sleeve labelers are designed according to the needs of each customer, in their customized project, can be equipped with a touch-screen screen, and have the MAQMUNDI PLC for control with production counter.

The ONE model has a DC motor and has an approximate hourly production capacity of up to 5,000 units. The PLUS model is equipped with an EASY-SERVO motor and has an estimated production of more than 6,000 units per hour, depending on factors such as speed and shape of the bottle to be labeled.

The equipment also has features such as: automatic unwinder, automatic cutting system with automatic application and quick change kit with template to assist in positioning, which facilitate the labeling process.

Check below a list of the main characteristics of the Sleeve Maqmundi MAQ-SLEEVE labelers and a video presenting the equipment, with several examples of applications in Cylindrical Bottles:

- Driven by cc Motors (Line ONE) and Driven by EASY-SERVO Motors (Line PLUS)

- Quick change kit with template to aid in positioning;

- Automatic cutting system with automatic application;

- Coil reading sensor;

- Automatic unwinding;

- CLP MAQMUNDI control with production counter;

- Protection cabin;

- Option to build in 1020 STEEL with epoxy paint or in STAINLESS STEEL;

- Voltage 220V/380V

- Production capacity per hour (estimated):

- LINE ONE: up to 5,000 units;

- PLUS LINE: over 6,000 units;

Would you like more information or a quote? Contact us through WhatsApp, by email contato@maqmundi.com.br or directly on the phone (47) 3383-0284.

You can also request a quote on our website, using the form on the product pages: model ONE and model PLUS.